Water conservation isn’t just about turning off the faucet while brushing your teeth. In industrial settings, particularly in manufacturing and automotive industries, the way water is managed and preserved significantly impacts operational efficiency and environmental responsibility. Among modern water saver products, systems like Proteus Industries' WeldSaver stand out for their intelligent, precise, and efficient water-saving capabilities.

This guide will explore how advanced water saver products work, when to consider using them, how the WeldSaver system functions, and why it’s an outstanding choice for smart water management. Whether you’re a plant manager, operations engineer, or sustainability officer, understanding these systems is key to reducing waste and enhancing productivity.

Explanation of How Water-Saving Products Help Reduce Consumption

A water-saving product is any tool, system, or device that minimises water usage without compromising performance. While we often think of low-flow faucets or smart irrigation systems in homes, industrial water saver products play a far bigger role behind the scenes in factories, automotive assembly lines, and commercial operations.

Water is extensively used for cooling in manufacturing processes such as robotic welding. The challenge lies in ensuring the water only flows when necessary, for example, while the welding gun is active. Wild or continuous water flow can result in tens of thousands of gallons of strained water over time.

Advanced water-saving products like the WeldSaver address this issue by actively monitoring water flow and detecting abnormalities. These systems are designed to automatically shut off water when it’s not needed or if a leak occurs. By doing so, they help industries significantly reduce water wastage, lower operating costs, and comply with environmental regulations.

In addition to immediate savings, these systems provide long-term benefits such as raising the lifespan of equipment by preventing water damage, avoiding costly downtime due to undetected leaks, and contributing to corporate sustainability goals.

Overall, modern water saver products are essential for any industrial operation serious about improving efficiency, reducing expenses, and being environmentally responsible.

When Should You Consider Using Water Saver Products?

The ideal time to consider integrating water-saver products into your operations is anytime water usage is continuous, repetitive, or prone to waste, especially when it contributes significantly to your operational costs or environmental footprint.

For instance, in automotive manufacturing and robotic welding, water is used constantly to cool the welding guns. Typically, without an intelligent monitoring system, the water continues flowing even when a robot arm is idle or during maintenance stops. This practice leads to considerable waste, often unnoticed until water bills spike or system failures occur.

Similarly, industries involved in plastic moulding, metal cutting, food processing, or chemical production often rely heavily on water for cooling or cleaning. Introducing water saver products in these sectors can drastically improve efficiency and compliance with water conservation policies.

Other signals that suggest it's time to adopt water-saving solutions include:

- Rising utility bills without clear increases in production.

- Frequent leaks or water-related equipment failures.

By integrating smart water saver products, operations can gain more control over their processes, prevent unexpected costs, and strengthen their reputation as environmentally conscious businesses.

How Does WeldSaver Work?

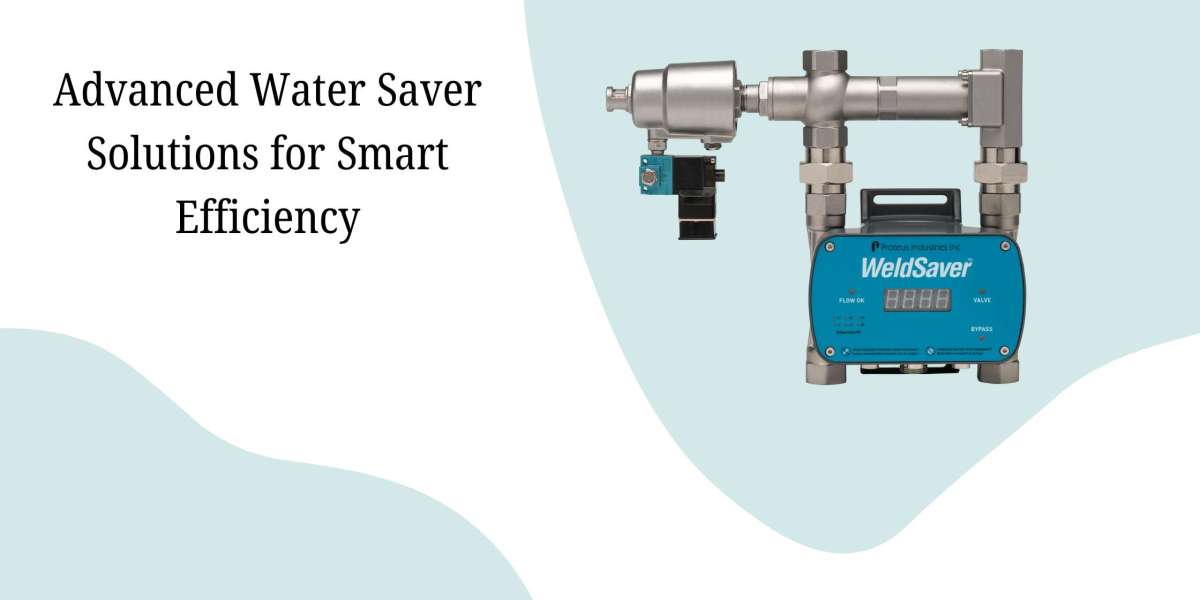

The WeldSaver system, developed by Proteus Industries, is a specialised water saver product designed for high-demand industrial cooling applications, especially robotic welding systems. What makes WeldSaver so effective is its ability to actively monitor water flow rates and temperature in real-time, detecting any abnormal conditions that could indicate a leak or equipment failure.

Water flows through the WeldSaver unit, which continuously measures flow rate and temperature using precision sensors. The system is calibrated to recognise normal operational parameters for each welding cell or cooling system. If the flow rate drops below, exceeds, or fluctuates beyond set limits, which might suggest a leak, blockage, or open weld gun, the WeldSaver reacts immediately.

It signals a fault to the machine controller and can instantly shut down the water flow using an integrated valve. This prevents further water loss, protects sensitive equipment from overheating, and alerts operators to take corrective action.

The Weldsaver's responsiveness and accuracy set it apart from basic monitoring systems. It reacts within milliseconds, stopping water flow before significant wastage occurs. It also includes diagnostic features and data logging options, enabling maintenance teams to analyse system performance and identify recurring issues.

In essence, WeldSaver isn’t just a flow switch; it’s an intelligent water-saving product built for demanding, high-speed, and high-risk applications where precision matters.

Why Choose WeldSaver for Water Conservation?

Among the growing market of industrial water saver products, WeldSaver offers several distinct advantages that make it a top choice for manufacturers and engineers:

- Real-Time Leak Detection: One of the most critical features of WeldSaver is its instantaneous leak detection. Leaks in robotic welding cells can lead to wasted water, higher operational costs, and even equipment damage. WeldSaver detects changes in flow rate immediately and triggers a system shutdown, preventing water loss and safeguarding expensive machinery.

- Rapid Response Time: Unlike traditional flow monitoring systems that may take seconds to react, WeldSaver responds within milliseconds. This ultra-fast response time is crucial in robotic welding applications, where a single second of delay could result in significant water loss or operational downtime.

- Flexible Integration and Configurability: WeldSaver can be easily integrated into existing or new manufacturing systems. It supports various flow rates and configurations, making it suitable for industrial applications. The system can be customised to specific operational parameters, ensuring optimal performance without interfering with production workflows.

- Comprehensive Data Monitoring and Diagnostics: Advanced water saver products should offer more than basic functionality. WeldSaver includes built-in diagnostics and data logging features that help maintenance and engineering teams track water usage trends, detect recurring issues, and optimise overall system efficiency. The data can also be valuable for sustainability reporting and regulatory compliance.

- Enhanced Equipment Protection: Continuous water flow when a system isn’t operational can cause wear and tear on cooling circuits and other sensitive components. By shutting off water promptly during idle periods or maintenance, WeldSaver prolongs the lifespan of equipment, reducing repair and replacement costs.

Conclusion

Water conservation has become a global imperative, not just for households and agriculture but for industries as well. Factories and manufacturing plants consume vast amounts of water daily, and any waste directly impacts both operational costs and the environment.

Fortunately, modern water saver products like Proteus Industries’ WeldSaver provide an intelligent, reliable, and efficient way to address this issue. By combining real-time monitoring, instant leak detection, rapid response shutoff, and comprehensive data diagnostics, WeldSaver ensures that water is used only when necessary, drastically reducing waste and protecting valuable equipment.

The benefits of integrating a system like WeldSaver go beyond immediate water savings. It extends equipment life, improves process efficiency, and aligns operations with stringent environmental regulations and corporate sustainability initiatives.

If your business involves robotic welding or any water-intensive industrial process, it’s time to consider the advantages of advanced water saver products. The WeldSaver isn’t just a practical addition it’s a strategic asset for smart, efficient, and responsible water management.